| 2025-09-11 |

WILDEN DISCHARGE ELBOWS

WILDEN® ANNOUNCES A CHANGE TO THE 51MM (2") PRO- FLO AND PRO-FLO SHIFT LIQUID CHAMBERS AND DISCHARGE ELBOWS

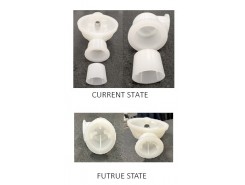

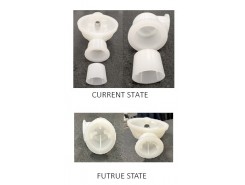

To simplify the production and repair of the 51 mm (2") Pro-Flo and Pro-Flo SHIFT pumps, Wilden has moved from having liquid chambers and elbows with separate ball cages to a design with integrated ball cages.

The item numbers for the adjusted liquid chambers and discharge elbows will not change. The affected item numbers are referenced below:

Item Number Item Description

WIL-08-5000-20 CHAMBER, LIQUID

WIL-08-5230-20 ELBOW, DISCHARGE MANIFOLD

This will be a running change. Pump orders may have a combination of pumps with the separate ball cages and pumps with the integrated ball cages until stock is depleted.

|

|

|

| 2024-11-15 |

WILDEN® ANNOUNCES THE OBSOLESCENCE OF 6 MM (1/4") PRO-FLO® & 6 MM (1/4") ACCU-FLO™ SERIES BOLTED PLASTIC AODD PUMPS

As previously annoiced in TB1728 Wilden® released a 6 mm (1/4") Pro-Flo® SHIFT Series bolted plastic AODD pump (PS25) and a 6 mm (1/4") Accu-Flo™ Series bolted plastic AODD pump (A25PS).

In support of providing a streamlined product offering for 1/4" bolted plastic AODD pumps, Pro-Flo® and Accu-Flo™ 1/4" models P25 and A25P will be obsolete, in one year from today, effective on July 31, 2024.

Wilden encourages our partners to incorporate the new product solution as the migration path from the P25 and A25P model pumps.

Obsoleting Product

Migration Path

Models P25 and A25P

Models PS25 and A25PS

Please contact our applications team at Wilden.QuoteSupport@psgdover.com to assist in finding an alternative solution for your application.

Thank you for your continued commitment to the Wilden brand. If you have any questions or would like to obtain a full list of obsoleted P25 and A25P models, please feel free to contact us.

|

|

|

| 2024-08-01 |

??????

???????? 2024?8?19??????????????2024?8?30??????????

??????2024?8?15?????, ????, ????.

|

|

|

| 2023-12-27 |

How to Select the Most Efficient Diaphragm for Your Wilden® AODD Pump

You can’t have air-operated double-diaphragm (AODD) pumps without the diaphragms. After all, it’s part of the name—and the design. But diaphragms are more than just components that fit inside your AODD pump.

Diaphragms help ensure the safe, efficient and cost-effective operation of your AODD pumps and contribute to extending pump lifespan, but only if you select diaphragms that suit your specific application, whether for wastewater, paints, food products, acids or any other substance.

However, selecting the right diaphragm can be challenging, especially since various diaphragm material options are available and every application requires unique performance characteristics.

Fortunately, Wilden® makes choosing the best diaphragm for your AODD pump simple. Let’s look at the factors you should consider when choosing the most efficient diaphragm for your AODD pump.

The Seven Factors to Consider When Selecting AODD Diaphragms

While operator expertise and familiarity with diaphragms offer a simple approach to diaphragm selection, even the most experienced operator should consider multiple factors before making their choice. After all, there is no one-size-fits-all diaphragm for every application.

To identify the ideal diaphragm for a specific application, the following seven key factors should be taken into account: abrasion resistance, chemical resistance, temperature ranges, adherence to sanitary standards, inlet condition, longevity and cost.

Abrasion resistance refers to how well the diaphragm can endure wear and friction caused by solids and particles present in the fluid being processed.

Chemical resistance evaluates how well the material of the diaphragm aligns with the characteristics of the processed fluid.

Temperature ranges encompass the diaphragm's adaptability and effectiveness across different temperature levels, including its performance under extremely high and low-temperature conditions.

Sanitary standards are particularly relevant for diaphragms utilized in food, beverage, and pharmaceutical settings, ensuring the diaphragm aligns with hygienic and sanitary requirements.

Inlet condition assesses a diaphragm's capability to transfer fluid between different locations.

Longevity, also referred to as flex life, represents the projected lifespan of the diaphragm before it needs replacement.

Cost involves various factors, including the initial price, anticipated application lifespan, costs incurred during downtime, and expenses associated with diaphragm replacement labor.

Now that we know what to consider when selecting a diaphragm, we can examine the three primary materials used for diaphragms.

The Three Primary AODD Diaphragm Materials

AODD pumps use three primary materials – rubber, thermoplastic elastomer (TPE), and polytetrafluoroethylene (PTFE). Each of these materials offers specific attributes that are well-suited for different applications.

Rubber

Rubber AODD diaphragms are created using synthetic rubber along with a nylon fabric mesh to enhance their flexibility. There are four types of rubber diaphragm materials: neoprene, Buna-N, EPDM, and FKM.

Neoprene is a versatile, cost-effective diaphragm intended for nonaggressive chemical applications, like water-based slurries and seawater. It is known for its longevity and abrasion resistance.

Buna-N is most effective when used with petroleum- and oil-based liquids, ranging from gasoline to turpentine. Also known as nitrile, this diaphragm offers moderate longevity and abrasion resistance, ideal for food and beverage applications.

EPDM serves as a low-cost alternative diaphragm when pumping diluted acids or caustics in food, pharmaceuticals, manufacturing, and paint and coatings applications. It is recognized for their good longevity and moderate resistance to abrasion.

FKM diaphragms are engineered to handle extremely high temperatures and aggressive chemicals like aromatic and chlorinated hydrocarbons. They possess a moderate level of longevity and abrasion resistance.

TPE

TPE AODD pump diaphragms are manufactured using injection molding, eliminating the need for fabric reinforcement seen in their rubber counterparts. These diaphragms offer four material choices: polyurethane, Wil-Flex®, Saniflex™ and Geolast®.

Polyurethane is a versatile diaphragm suitable for nonaggressive chemical applications like water and wastewater, demonstrating outstanding longevity and abrasion resistance.

Wil-Flex, a cost-effective alternative to PTFE, is ideally designed to handle corrosive fluids like sodium hydroxide and hydrochloric acid in chemicals, pharmaceuticals and wastewater applications, offering excellent longevity and abrasion resistance.

Saniflex, made of Hytrel®, offers low compression set characteristics, good longevity and excellent abrasion resistance, making it ideal for food processing applications.

Geolast, similar to (Buna-N or Buna-TPE), is most commonly used in petroleum applications due to its extreme oil resistance and low oil swell. It Offers moderate longevity and good resistance to abrasion.

PTFE

PTFE can be used with a wide range of fluids, even highly-aggressive variations like hydrocarbons, acids, caustics, ketones and acetates, offering excellent longevity and moderate abrasion resistance in pharmaceutical and food and beverage applications.

However, PTFE is non-elastic, so a backup diaphragm made of different materials is required for memory and flexibility. Neoprene, Saniflex and high-temperature Buna-N are ideal backup diaphragm options.

The Diaphragm Selection Guide

To optimize the performance of your AODD pump, you should carefully choose the most suitable diaphragm for your specific application—and selecting the right diaphragm means carefully identifying and considering multiple factors and application requirements.

|

|

|

| 2023-12-06 |

Best Bond PEVA Pipe Support Job reference

West Kowloon Cultural District - Use for Chilled water pipe

Haven of Hope Hospital - Use for PIP pipe

Penny's Bay Quarantine Center - Use for Water and Refrigerant pipe

|

|

|

| 2023-10-30 |

|

| 2023-06-29 |

Wilden® Minimizes Product Recalls With Saniflo™ Hygienic™ Series AODD Pumps

From a delicious home-cooked meal to a relaxing glass of wine, food and beverages provide the nutrients and satisfaction that are essential to life. That’s why food and beverage operations are tasked with following strict health regulations to help ensure a variety of products remain safe for human consumption. However, food and beverage processors are faced with many challenges, including product recalls and loss from contamination.

“Manufacturers are doing everything possible to avoid product recalls or losses,” says Tom Zuckett, Americans Northeast regional sales manager for PSG®. “That’s why we’ve designed our Wilden® Saniflo™ Hygienic™ Series Air-Operated Double-Diaphragm (AODD) Pumps to be highly cleanable and drainable.”

One–Of–A–Kind Design

Saniflo Hygienic Series Diaphragm Pumps are designed for the high-cleanliness requirements of food and beverage applications. The flow-through liquid-path design eliminates any potential areas where residue can become trapped. At the same time, the free-draining flow path provides quick and easy draining without needing to disassemble the pump, allowing for clean-in-place (CIP) capability. This state-of-the-art design helps simplify cleaning and ensures high cleanliness, further reducing contamination risk, costs and downtime. In fact, the Saniflo Hygienic Series is the only US-manufactured AODD pump in the industry to have 3A certifications for CIP operations.

“Additionally, when equipped with Wilden Pure-Fuse Integral Piston Diaphragm (IPD) technology, the common bacteria trap in standard diaphragms is eliminated,” Zuckett says. “Pure-Fuse diaphragms are also much easier to clean between product changeovers and have a much longer service life. Because the diaphragm doesn’t hold back fluids, bacteria traps are eliminated.”

The AODD pumps also help in production environments commonly manned by new operators, Zuckett points out. “These operators have fewer skills, so air-operated systems are easier for them; they’re more forgiving,” he says.

Energy efficiency is also a factor for Saniflo Hygienic Series pumps thanks to the Wilden Pro-Flo SHIFT air distribution system (ADS). The design of the Pro-Flo SHIFT optimizes the Saniflo Hygienic Series’ performance by lowering air and energy consumption, increasing productivity, minimizing maintenance and reducing compressed air costs by up to 60%.

The responsibility that comes with handling products intended for human consumption is challenging. For this reason, food and beverage operations need simple, reliable and energy-efficient Saniflo Hygienic Series Pumps to help operations provide the food and beverages people enjoy and need by minimizing the risk of product recalls and loss due to contamination.

|

|

|

| 2011-06-30 |

香港卡特彼勒 (Caterpillar) 把一台用了超过25年的水力测功机从2,500 提升至3,000 HP

香港卡特彼勒 (Caterpillar) 把一台服务超过25年的Power Test水力测功机由原来最大2,500 HP测试功率提升至3,000 HP.

这是一台经得起时间考验和赢得用户信赖的水力测功机。它背后全依靠30年前制造商精心制作的可靠和耐用的零配件。对于由制造商不断完善及提升产品质量时而衍生的小改动,我司在这方面全力协助客户选配、更换及组装备件。由于测功机的吸收器不变,所以这台超过25年的人工模式控制设计的Power Test水力测功机,客户是可以很轻松地升级到现在Power Test全自动测功器控制和数据采集系统标准规格。

升级工程已于今夏六月完成,升级后的Power Test水力测功机亦继续投入为客户服务了。

|

|

|

| 2010-01-13 |

中华电力龙鼓滩发电厂

After the sucessful modification for the two air intake chambers of the gas turbine gensets for the CLP Power at the Black Point Power Station in Hong Kong, Freudenberg's Compact Pocket Filter T 60 has gained approval and trusted by the station's management team. The T 60's outstanding performance was proved by our client after a 14 month continously operation without replacement. As advised, a filter replacement had to carried out every three to four months before our modification. The modification has already shown a big return of money by no filter replacement and less air pressure differential during the last 14 months. Therefore, higher power output and no loss of power during filter replacement is acheived.

For more details, please contact Edmond Yan

e-mail: edmondyan@meritoneast.com

|

|

|

| 2009-06-30 |

香港政府船坞拥有全港最先进的柴油发动机动力测试和废气排放分析系统

香港政府船坞维持795多艘大小不一的运作船,当中约116艘为较大的机动船,约75艘为快艇。政府船只的例行保养定期进行,修理则于必要时进行,约90%交由认可私人承办商做,其余则由船坞技术员工负责。政府船坞维修组监察承办商的工作表现并确保工程遵照规格完成。

2008年秋季,香港政府船坞决定把目前的Power Test柴油发动机测功机和人工数据采集系统升级,以满足现在对动力和废气排放测试的要求。政府船坞要求美国Power Test公司提供协助。作为美国Power Test公司的香港和中国合作伙伴,我们在2009夏季成功为政府船坞完成改造、安装、调试和现场操作培训(包含理论和实践)。新系统是目前香港最先进的一体化柴油发动机测功机连电脑数据采集和废气排放分析系统。

新系统包括:

1. 一台改造现有的Power Test 25X08水力测功机

2. 一套全新海水冷却钛合金片式热交换器

3. 一套全新Power Test燃油测量系统

4. 一套全新Power Test PowernetLT测功器控制和数据采集系统

5. 一套全新Lancom-III 9种排放气体分析系统

如需项目详情,可联系我司甄德铭,电邮: edmondyan@meritoneast.com

|

|

|